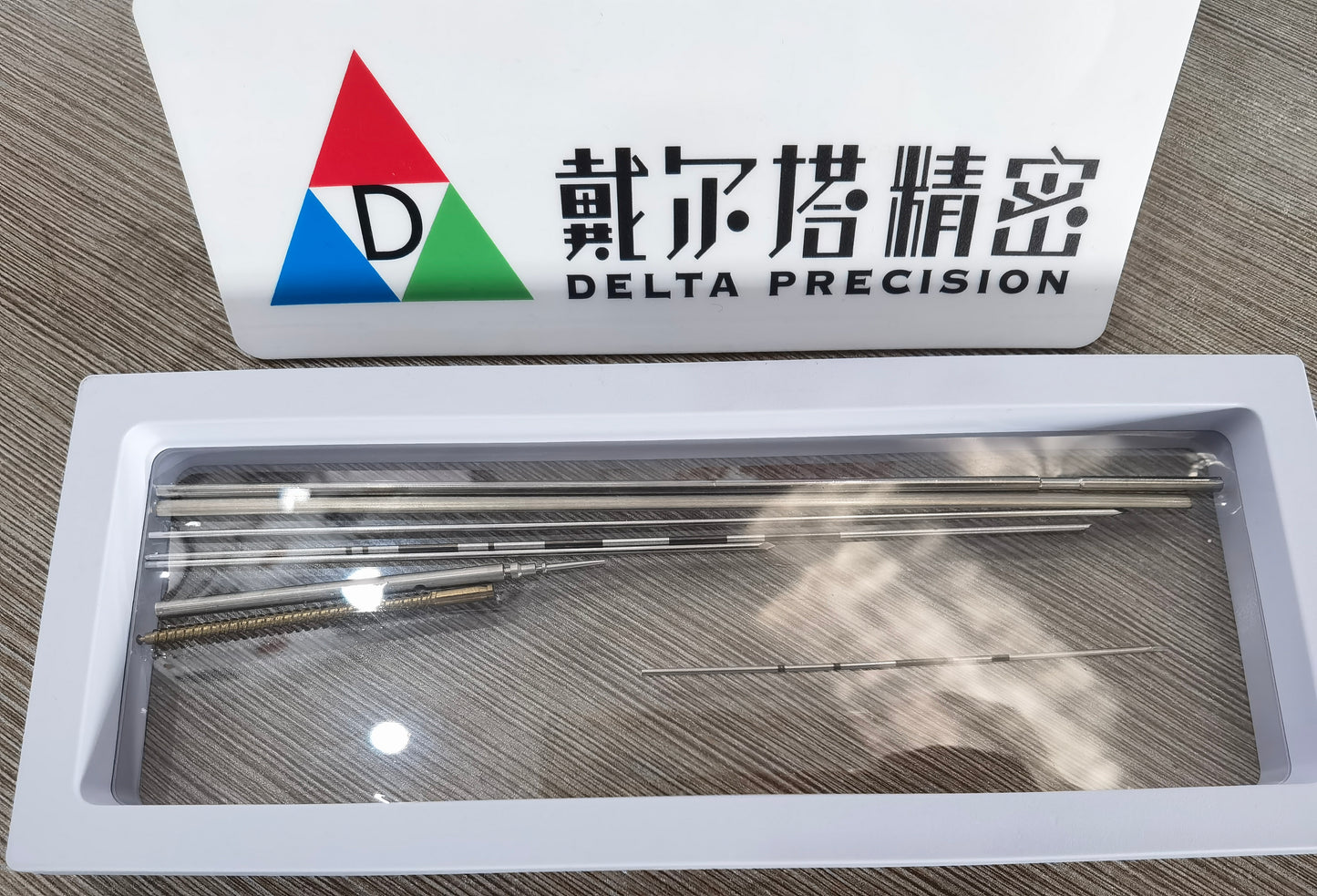

Delta precision

Contract manufacturing of medical devices

Contract manufacturing of medical devices

无法加载取货服务可用情况

Welcome you to visit DELTA Precision store!

All pictures on show are a prototype sample, not for sale. If you have any RFQ,please see below RFQ process.

Delta is a precision and injection molding one-stop manufacturer, focus on high precision micro parts customization-Since2004, is Certified by IATF16949, ISO13485 and ISO14001

The main process is CNC turn-milling composite processing, with micro-hole processing, wire rolling, high-precision grinding, laser welding, laser cutting, wire cutting, welding, Teflon spray, electrolytic polishing, passivation, injection molding and other processes to provide high-precision parts manufacturing solutions for high-speed rail, automotive, aviation, medical, precision equipment and other industries.

We have always attached great importance to the customer's quality specifications, no matter how strict, we will do our best to meet.

DELTA has grown over the past decade to develop a wide range of high-precision components for large customers. With the technical advantages of our company, we know how to solve all the problems you may encounter.

- Manufacturing capability - parts processing

- CNC machining services

- CNC lathe/turning services

- Full automatic turning and milling compound

- Prototype Sample Part and Batch Production

- Precision parts processing service

Numerical control machining

- Min machining diameter:0.1mm

- Max machining diameter:50mm

- Machining precision:±0.005mm

Finish machining

- Laser cutting, EDM forming, line cutting

- Laser marking

- Laser welding, manual welding

- High frequency welding, argon arc welding

- The minimum diameter of microhole machining is 0.05mm

- Surface grinding and polishing machining accuracy 1Mu

- Centerless grinding

- Grinding: Machining diameter :3-80mm

- Surface grinding machine: accuracy is 5Mu

- Center hole grinding,

- Top core mill, punch grinder

- Milling machine

Post-processing

- deburring

- Electrolytic polishing (qualified for EIA)

- Passivation (qualified for EIA)

- Teflon spray

- Pad printing

- Ultrasonic cleaning

- Abrasive flow polishing

Machinable metal materials

- Carbon steel, copper, aluminum, stainless steel, titanium alloy, pure titanium, pure molybdenum, pure nickel, Nitinol, platinum-iridium alloy, tantalum, cobalt-chromium alloy

- Customized Products

Ophthalmic surgical instrument parts

Cochlear parts

Vascular suture apparatus parts

Heart operating instrument

Brain pacemaker parts

-

Quality management

- laboratory

- material pulling machine

- the spectrometer

- measurement

All product sizes can be inspected in the factory.

Zeiss CMM,Mahr cylindericity instrument, Microscope,projector, hardness meter, height gauge, roughmeter and etc.

full thread go-stop gauge, thread ring gauge, hole plug and etc.

be equipped with air gauge AEC-300 accuracy within 1Mu

- Visual check: We always check, not to miss any detail

- Order management

Dedicated customer service handles orders in the first time,docking with customers, PMC makes internal planning and material control, and delivers goods strictly in accordance with the contract delivery date.

- Logistic management

We can delivery all over the world by sea, air, train or express.

- Summary-our advantages

. One-stop manufacturing solutions for you from parts processing to medical device assembly;

. Stable precision machining process is more suitable for mass production;

. Proofing success rate is guaranteed;

. From raw materials to finished product control, quality is never compromised;

. The main processes are produced in the factory, and the supply chain is shorter and more reliable;

. Focus more on delivery than the customer;

- RFQ PROCESS:

All pictures on show are a prototype sample, not for sale. If you have any RFQ,please see the following process.

- Please kindly send your drawings to us for RFQ.

- Our engineers will carefully evaluate your drawings, if there is any technical problem, we will confirm with you.

- Make offer to you, including sample price & mass production price & logistics fee and delivery time.

- Receiveyour order and the sample fee.

- Make sample for you.

- Get the approval of sample.

- We received the advanced payment for mass production.

- Start the mass production for you.

8.Contact information:

Press contact button to contact us or call us.

We thank you for your trust and support. We hope our high precision parts brings you complete satisfaction.

Best Regards

DELTA Precision E-commerce Team

Share